Electric Vehicles/Battery

Electric Vehicles/Battery

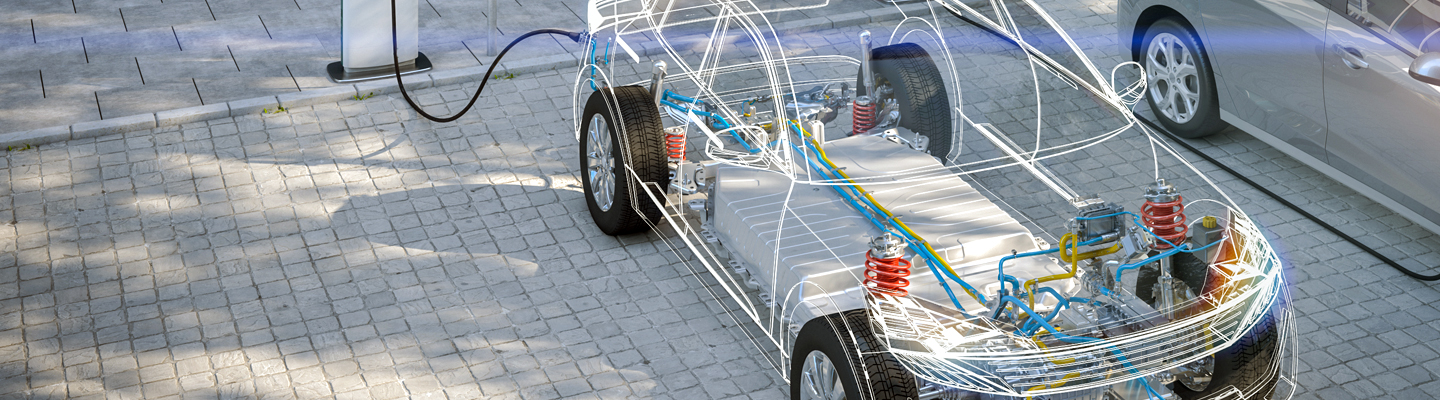

People are seeking sustainable and environmentally friendly technology to counteract climate change and reduce their carbon footprint. Demand for electric vehicles, batteries, and the accessories needed to ensure they function in peak conditions are definitely growing exponentially.

Novagard’s electronics grade silicones offer dependable performance, allowing for increased power density in emerging battery technologies. They provide maximum stress relief, superior protection against shock and vibration, and their high dielectric strength makes them excellent electrical insulators.

Applications:

- Battery pack thermal gap fillers

- Charging systems

- Computer control modules

- Wiring harness pin connectors

- EV-ECU potting, sealing, coating

- Sealing and encapsulating sensors

- Headlamp assemblies

-

Electronics Grade (Alkoxy) Silicones

500-PV is a two-component, alkoxy condensation cure silicone thixotropic paste. 500-PV is ideal for assembly of PV solar panels, frames, and junction boxes.

500-210 is a balanced-performance clear sprayable silicone coating featuring a room temperature alkoxy moisture cure that can be accelerated with heat. This silicone is UL 746E certified and has a V-1 rating for flammability.

500-228 cures to a tough, strong, resilient gel to provide protection from both physical damage and mechanical stress and strain relief in addition to great dielectric properties.

500-09x is a high performance UL-rated electronics adhesive. This one-part UL flame rated paste is for applications that require superior bond strength and flame resistance.

-

UV Cure and UV/Dual Cure Silicones

800-401 is a UV-only, fast-curing paste with adhesion to many plastics. With nominal viscosity of 300,000 cPs, 800-401 consistently holds its shape even when dispensed into complex shapes.

800-754 is a UV-cure only pottant that cures to a soft, compliant elastomer that relieves stress and strain on delicate components. 800-754 will UV-cure to a depth of 14mm in a single pass.

800-755 is an incredibly soft non-corrosive, single-component gel and is an ideal pottant or encapsulant that will also dramatically increase your throughput.

800-260 is a first-generation conformal coating for printed circuit boards. While its oxime secondary moisture cure provides improved physical properties, it offers limited adhesion and can present potential corrosion issues in enclosed applications. This silicone is rated UL 746 E and V-1.

With viscosity of 50,000 cPs, 800-750 clings readily to components for staking and glob-top applications.

800-230 is a UV curable self-leveling silicone pottant that offers a higher viscosity coating option, while still remaining flowable.

800-235 is UV-cured, semi-flowable material. A UV-cure only silicone with limited adhesion, its higher viscosity makes it ideal for cured-in-place gaskets.

800-400 is a UV-only, fast-curing paste without adhesion. With nominal viscosity of ~300,000 cPs 800-400 consistently holds its shape even when dispensed into complex shapes.

800-520FC is a UV-curable, silicone conformal coating, pottant, or sealant. 800-520FC will cure to a solid elastomer in seconds upon exposure to ultraviolet (UV) light.

800-550 is a UV-curable, silicone coating, pottant, or sealant. With a viscosity of 5,500 cPs, 800-550 flows readily to surround the complex geometry of modern circuitry design.

800-505FC is a UV-curable, silicone conformal coating with a secondary, neutral alkoxy moisture cure for enhanced adhesion and shadow cure. It is UL 746E certified with a V-1 rating for flammability. Utilizing our Fast Cure technology, this secondary moisture cure begins immediately and develops full adhesion in hours.

-

Addition Cure Silicones

600-251 is a platinum catalyzed, room temperature, addition cure silicone for potting and encapsulant applications requiring thermal conductivity.

600-250 is a flowable, platinum catalyzed, addition cure, durable encapsulant with good dielectric properties and flame resistance. The high (>90%) transparency of 600-250 allows for easy inspection of components.

-

High Temperature Foams

60-HTA is a soft, high temperature closed cell foam designed for applications requiring a low force to compress, and for filling large voids and variable gaps.

100-HTA is a high temperature closed cell foam designed for applications requiring both flexibility and strength, and balances compressibility with increase strength and wear resistance.

150-HTA is a high temperature closed cell foam designed for applications requiring a cushion against heavy loads, and withstands wear and abrasion in “tough duty” applications.

-

Specialty PVC Foams

Aluma-Seal is a medium density, closed cell PVC foam that acts as a thermal insulator to prevent condensation build-up on surfaces to which it is applied.

Aluma-Seal is a UL 723 classified, closed cell PVC foam used as an insulator for HVAC plenums, pipes, and pans to prevent condensation build-up on surfaces to which it is applied.

70P UL is a low density closed cell PVC foam formulated to conform to UL HF-1/HBF for use as an ANSI/UL94 approved component in electronic applications.

Mylar is a closed cell PVC foam that is very effective in a variety of non-critical sealing applications.

-

Dielectric Compounds and Lubricants

G623 is specifically formulated for use as a water repellant coating to prevent corrosion, especially in critical applications that require good dielectric properties.

G624 is specifically formulated for use as a water-repellent coating to prevent corrosion and conforms to SAE AMS-8660 (formerly SAEAS-8660 and Mil-S-8660C). G624 is an alternative to DuPont Molykote 4 (DC4).

With lower operating temperature (ranging from -57°C to 200°C), G635 is an excellent dielectric compound with good moisture barrier and corrosion resistance properties. G635 can be used as an alternative to Dow Corning DC 5.

G661 seals and protects electrical connections above and below ground. G661 is most frequently used as a valve and O-ring lubricant, and can be used as an alternative to Molykote 111 Compound (Dow Corning's DC111).

G662 seals and protects electrical connections above and below ground, and is certified to NSF Standard 61 for Drinking Water System Components. G662 can be used as an alternative to Molykote 111 Compound (Dow Corning's DC111).

Designed for use as a dielectric compound on high voltage insulators, G687 reduces the opportunity for dirt and moisture to create arcing across the insulator. It can be used as an alternative to Dow Corning / DuPont Molykote HV3099.

G697 can be used as a lubricant on unpainted ferrous metal surfaces (threaded or unthreaded) to help prevent corrosion, and maintain the condition of the substrate. G697 conforms to MIL-DTL-21567B (formerly MIL-C-21567C).

-

UL Approved PVC Foams

Aluma-Seal is a UL 723 classified, closed cell PVC foam used as an insulator for HVAC plenums, pipes, and pans to prevent condensation build-up on surfaces to which it is applied.

70P UL is a low density closed cell PVC foam formulated to conform to UL HF-1/HBF for use as an ANSI/UL94 approved component in electronic applications.

-

NSF Silicone Lubricants

G662 seals and protects electrical connections above and below ground, and is certified to NSF Standard 61 for Drinking Water System Components. G662 can be used as an alternative to Molykote 111 Compound (Dow Corning's DC111).

-

Thermally Conductive Compounds

G641 offers excellent heat transfer in large and small electrical and electronic components and is an ideal material for use in thermocouple wells, power diodes, transistors, semiconductors, and ballasts. G641, or G644 can be used as direct alternatives to Dow Corning / DuPont Molykote DC340.

Versilube G644 is a softer, lower viscosity version of the original Novagard thermal compound, G641. Both G644 and G641 can be used as direct alternatives to Dow Corning / DuPont Molykote DC340.