- Markets

- Products

- Resources

- News & Events

- How To Buy

SUGGESTED SEARCHES

As an innovator and manufacturer of silicones, a talented, robust R&D team ensures that the products we produce meet or exceed our customers’ expectations.

We have significant expertise and experience in a wide array of technical disciplines including Polymer Physics, Polymer Engineering, Synthesis, Chemistry, Formulation, Analytical Sciences, Foam, and Cellular Materials. Our technical team includes experienced Ph.D. scientists and engineers along with subject matter experts in the development of sealant applications for the electronics, automotive, industrial, and building and construction industries.

Our R&D team is vital to our future. We’re building on our core competencies by hiring additional scientists, engineers, and technicians who strengthen our capabilities and bring a creative and pioneering mindset to product development. We continue take advantage of technological advancements by investing in equipment to test thermal, electrical, and physical properties, expedite the commercialization process, and simulate customers’ testing and manufacturing environments.

The spirit of innovation flows through our labs. Working together with technical sales managers, we focus on the problem or barrier our customers are trying to overcome. We are very proud of our heritage of customizing and developing products to meet our customers’ specific needs – we’ve introduced over 60 new products to the market since 2018.

With the electrification of everything, we see how silicones could play a much larger role in the manufacturing process. In 2019, we began designing our proprietary alkoxy silicone polymers and advanced adhesion promotors and crosslinkers. We are advancing the next generation of electronics and high performance products by tailoring silicones with a broad, customizable range of cure times, physical properties, and rheologies to fit the specific application.

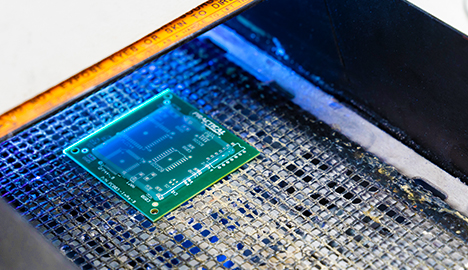

We developed a revolutionary curing technology that is transforming the manufacturing process for electronics. Our UV/dual cure product line seals and protects sensitive electronics applications with a UV primary cure that dries tack free in seconds, paired with a secondary alkoxy moisture cure that builds adhesion to common electronic substrates while eliminating unreacted coating in shadow areas. By combining the speed of UV curing with the safety and completeness of a non-corrosive alkoxy moisture cure, we offer a unique ability for cure in both the exposed and shadow areas.

NovaTherm silicone-based thermal management materials offer excellent heat dissipation over a wide temperature and humidity range, making them particularly useful for protecting electronics in extreme conditions. Along with thermal conductivity, they provide adhesion, rapid assembly, and environmental protection.

We can tailor the uncured and cured physical properties of our silicones for complex thermal interface management needs. The thermal filler package can also be modified to impart specific performance characteristics. Our polymer technology capabilities extend to adhesion promoters, which have changed the game in terms of what is possible in adhesion performance.

Novagard has a long history of supplying silicone sealing adhesives to the window industry. Recent innovations have focused on reducing production time and achieving higher throughput. Qwik-Set Glazing Sealant is a groundbreaking, new product that cures in minutes rather than days, allowing for movement of assemblies within minutes of application without glass shifting. Qwik-Set won a Door and Window Market [DWM] Magazine’s 2021 Readers’ Choice Award and was named a WinDoor 2021/22 Product of the Year.

We are also making advancements in the secondary sealant market for Insulated Glass (IG). These single-component, quick-setting silicone IG sealants speed the manufacture of IG units. Our IG sealants are now in extended trials and are expected to be commercialized in 2023.

For our construction and installation customers, we now offer a complete line of professional grade construction products. Our silicone adhesive sealants are used for windows, doors, siding, gutters, roofing, and expansion joints. And we manufacture installation and repair materials for both commercial and residential roofing projects.

In addition to our silicones, we have hybrid polymer-based sealants. Hybrids offer some advantages over silicones, particularly for those applications requiring paintability. Our hybrid products provide an excellent balance between rate of cure, adhesion, and physical properties, and are available in a variety of viscosities and performance characteristics.

We continue to improve and refine our Foam Seal PVC Foams. During the midst of the COVID-19 pandemic, we launched our Medical Grade Foam. This foam has been independently tested and certified to comply with the ISO 10993-10 protocol for direct skin contact. It’s used for face shields, face masks (N95), diagnostic devices, and therapeutic accessories.

We also offer a line of High Temperature foams that are a cost effective replacement for crushed EPDM and outperform more

expensive EPDM alternatives.